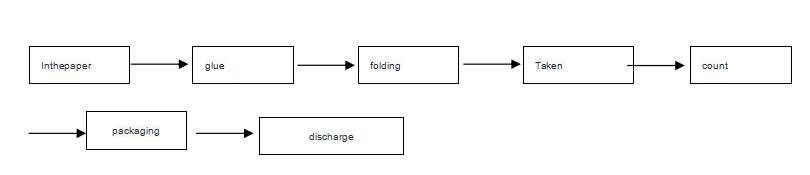

2. Function description of the box sticking machine The gluing part: the gluing part adopts the non-stopping method or the gluing system to avoid the easy adjustment of the gap of the glue curing rubber wheel. Dial suitable for glue between 1 and 9mm thickness of cardboard. The amount of glue is easy to adjust. In order to improve the speed of the bridge and flexographic printing slotting production speed synchronous adjustment. At the same time, the folding belt and the conveyor belt produce flexible printing slotting at almost the same speed, avoiding the folding machine and the waterborne printing slotting part being out of sync, which may cause the cardboard to get stuck, and achieving accurate delivery. The upper and lower belt speed can be adjusted separately, that is, their speed is different, it can be adjusted to the same speed. Folding board with or rubber drum, easy to adjust the folding Angle. The feeding part adopts spring pressure to adjust the clearance, and the thickness of the paperboard is automatically adjusted between 1 and 9mm. Cardboard stacking and counting pieces. Stacking paperboard by mechanical way and sensor, realize automatic. Counters (sensors) count the number of cartons, easy to set up and reliable. Stacked cardboard uses computer counting and precise pushing. 3. The instruction manual Technical data according to flexographic slotting specifications

2. Function description of the box sticking machine The gluing part: the gluing part adopts the non-stopping method or the gluing system to avoid the easy adjustment of the gap of the glue curing rubber wheel. Dial suitable for glue between 1 and 9mm thickness of cardboard. The amount of glue is easy to adjust. In order to improve the speed of the bridge and flexographic printing slotting production speed synchronous adjustment. At the same time, the folding belt and the conveyor belt produce flexible printing slotting at almost the same speed, avoiding the folding machine and the waterborne printing slotting part being out of sync, which may cause the cardboard to get stuck, and achieving accurate delivery. The upper and lower belt speed can be adjusted separately, that is, their speed is different, it can be adjusted to the same speed. Folding board with or rubber drum, easy to adjust the folding Angle. The feeding part adopts spring pressure to adjust the clearance, and the thickness of the paperboard is automatically adjusted between 1 and 9mm. Cardboard stacking and counting pieces. Stacking paperboard by mechanical way and sensor, realize automatic. Counters (sensors) count the number of cartons, easy to set up and reliable. Stacked cardboard uses computer counting and precise pushing. 3. The instruction manual Technical data according to flexographic slotting specifications | 200 | |

| Maximum speed(mm) | 350 |

| Minimum stacking height(mm) | 80 |

| 30 | |

| Maximum number of sheets in a pile (sheets) | 10 |

| Maximum paper size (mm) | 1000x2200 |

| Minimum paper size (mm) | 170x450 |

| Maximum size of glue side (mm) | 700 |

| Minimum size on the other side (mm) | 65 |

| Chief,(m) | 10.5 |

| Corrugated type | A,B,C,E,A+B,B+C,B+E |

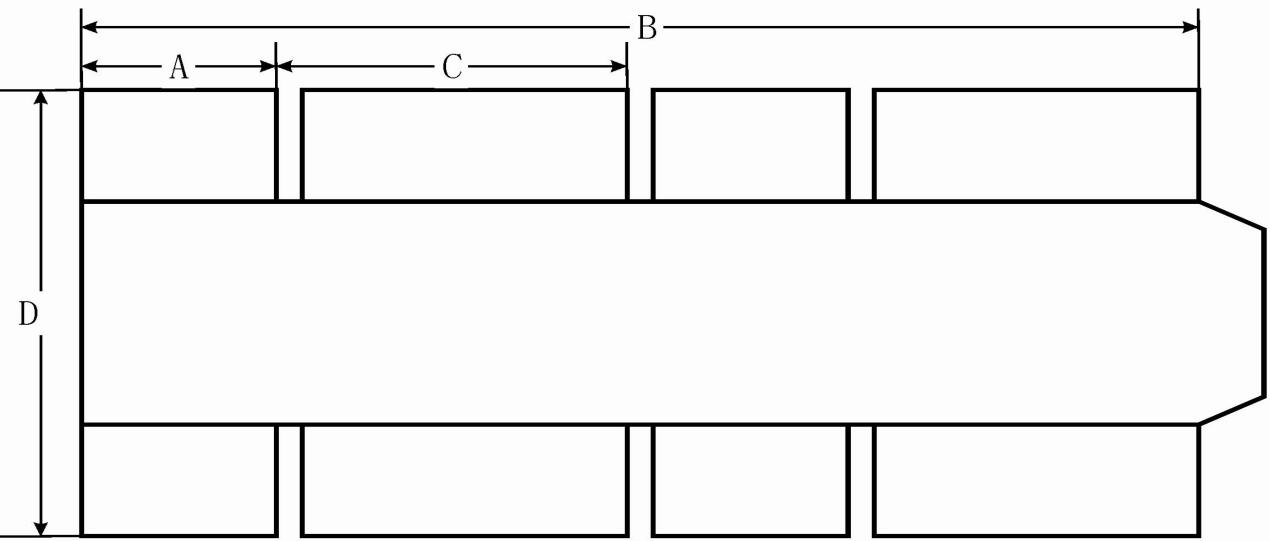

Paper processing parameters

Schematic diagram of carton processing

| model | 2200type |

| sizeA(mm) | 80-660 |

| sizeB(mm) | 420-2000 |

| sizeC(mm) | 135-660 |

| sizeD(mm) | 170-1000 |

| Installation area (mm) | 10-3.5 |

| Motor power (KW) | 8kw |

| Machine weight (T) | 5.5T |